Mastering the Craft: Welding Services by Cypress Fabrication

In the industrial heartland of Lafayette, Louisiana, where precision meets passion, Cypress Fabrication proudly stands as a beacon of excellence in...

3 min read

Cypress Fabrication Services

:

May 9, 2024 10:00:00 AM

Cypress Fabrication Services

:

May 9, 2024 10:00:00 AM

Exotic metals can be a great option for projects that require special properties or characteristics. In this blog post, we'll take a look at some of the most popular exotic metals used in piping fabrication, as well as their key benefits and application. Whether you're considering using an exotic metal for your next project or just want to learn more about these materials, read on for everything you need to know!

1. Benefits Of Working With Exotic Metals

2. The Process Of Working With Exotic Metals

3. Commonly Used Exotic Metals

4. Industries That Benefit Most From Exotic Metals

Working with exotic metals can be extremely beneficial for a number of reasons. Firstly, exotic materials can often provide increased strength or performance qualities where regular materials fall short. These metals are often more durable than traditional materials, as they are resistant to higher temperatures, corrosion, or radiation, resulting in longer life spans, and requiring less maintenance.

Additionally, these metals are often much lighter than their traditional counterparts, making them ideal for items that need to be lightweight without sacrificing durability. This quality makes them especially useful in the construction of certain aircraft and vehicle parts that must meet certain weight requirements as mandated by manufacturers.

Exotic metals also have some aesthetically pleasing properties; many feature interesting colors or patterns that can give any item a unique touch. Ultimately, working with exotic metals has several advantages when it comes to functionality, making it an excellent choice for a variety of projects.

Piping fabrication using exotic metals is a complex process that requires special tools and expertise. The first step in any project is to determine the desired material and its properties, as well as the size of the components needed for the job. Once this information has been gathered, a sample can then be examined to ensure that it meets all requirements for the specific project.

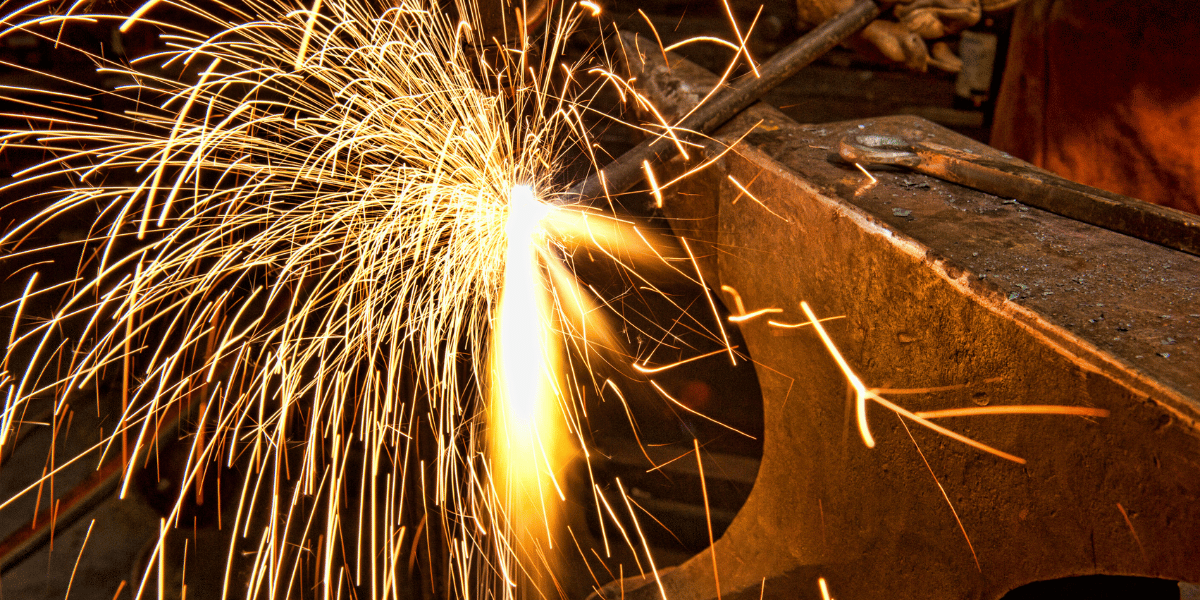

After the material has been adequately tested, it is then cut to the desired size and shape according to the project’s specifications. This process can involve cutting, grinding, welding, or any other methods necessary for proper fabrication. When everything is done as per requirements, the parts are then polished and prepared for installation into the system.

Cypress Fabrication specializes in the handling of exotic metal materials. Our approach to metalwork is focused on keeping quality and compliance as primary goals. This means that we pay careful attention to ensure that the metal is cut, bent, or welded according to precise measurements and tolerances. Every stage of the fabrication process involves strict standards that exceed ASME requirements.

Exotic metals are unique alloys that are used in a variety of engineering and manufacturing applications. Each of these exotic metals can offer manufacturers unique properties that standard-grade steels do not possess.

Carbon steel is one of the most common exotic metals and is used in sectors from automotive to aerospace manufacturing. Carbon steel is often chosen because of its superior physical properties, including high strength and wear resistance.

Stainless steel offers increased corrosion resistance, making it ideal for outdoor infrastructure such as handrails and shelving. Its excellent aesthetic properties are also a key factor in its popularity, as stainless steel can be polished to create a wide range of different finishes.

Nickel alloys offer superior strength and corrosion resistance, making them perfect for high-heat applications such as oil refineries or exhaust systems. They are also popular in cryogenic applications, as they can withstand extreme temperatures.

Titanium alloys are prized for their durability and strength-to-weight ratio. Titanium is also nonmagnetic and noncorrosive, adding to its appeal in many industrial applications. It has also become popular in the medical sector due to its biocompatibility with human tissue.

Aluminum is lightweight, non-magnetic, and corrosion-resistant, making it a popular choice for aerospace projects as well as corrosion-resistant wall panels. It is also relatively inexpensive and easy to shape into any desired form.

Copper Nickel offers extremely high strength and ductility at elevated temperatures and has been used in oil and gas industries around the world. It is also prized for its corrosion resistance, making it a great choice for coastal engineering projects.

Super Duplex is typically used in industries like offshore oil and gas production or maritime transportation due to its superior strength over traditional stainless steel. Its excellent corrosion resistance and high-temperature strength make it ideal for a wide range of marine engineering applications.

Industries ranging from the automotive, construction, and aerospace benefit greatly from the incorporation of these materials in the design and build of their products. Exotic materials are also transforming the manufacturing industry, allowing engineers to create components with far greater durability and complexity than with traditional elements alone.

Other industries include:

At Cypress Fabrication, we have over a decade of experience helping clients with their exotic metal components needs. We are dedicated to providing you with durable and precise metal works while ensuring safety and efficiency with every item we produce.

We work with all types of companies in the Oil and Gas industry and can help you with projects big and small. If you’re looking for someone to partner with on your next project, give us a call. We’d be happy to provide you with a quote for our fabrication services.

At Cypress Fabrication Services, we are a leading ASME-certified metal fabrication company with over twenty years of experience in the oil and gas industry. We specialize in custom metal fabrication for upstream, midstream, and downstream operations. All of our products are designed and fabricated to meet your specific process requirements, as well as various industry standards including our DNV skid certification, ABS certification, ASME pressure vessels, and AISC fabrication.

In the industrial heartland of Lafayette, Louisiana, where precision meets passion, Cypress Fabrication proudly stands as a beacon of excellence in...

Metal fabrication is a process that encompasses the entire production of metal components from raw materials to finished goods. It's versatile,...

When you're looking for the best metal fabrication company for your specialized project in the oil and gas industry, there are four main requirements...